Training the Next Generation of Insulation Pros

The construction industry depends on skill, precision, and consistency. This is especially true for the professionals who choose and install insulation products in new buildings and renovations.

Training new insulation pros is a high-return investment that companies can make to maintain quality and efficiency on projects. Yet, as any experienced contractor knows, onboarding new insulation professionals isn’t always simple. From learning building codes to understanding foam behavior, there’s a steep learning curve that can lead to costly mistakes if not addressed properly.

That’s why we emphasize practical, hands-on training with our TYTAN Professional products. This will build confidence in new employees and make their job less complex.

The Training Challenge

Every job site presents a unique set of conditions. Even houses built from the same plans can vary based on how the wood was cut, how it settles over time, or moisture levels in the environment. These small differences can lead to gaps, leaks, or failed blower door tests if installers don’t understand how to adapt their methods and materials.

New installers tend to face three main challenges:

- Understanding building codes and inspection requirements

- Choosing the right spray foam or adhesive for the job

- Applying insulation correctly for consistent, efficient results

A mistake with foam selection, preparation, or technique can cause inspection failures, rework, wasted material, and frustrated builders. That’s why structured, intentional training is key to developing skilled installers who can confidently apply the right product in the right way.

Spray Foam Insulation Training

New installers need a solid grasp of spray foam insulation types, required preparation processes, and correct application techniques. We recommend focusing on a few core areas early in training:

Product Selection

Window and door foams, fire block foams, and polyurethane insulation foams all behave differently. Those in charge of choosing materials for each insulation area on a project must understand the available options and where they perform best. For example, using a high-expansion foam—for example, TYTAN Fire Block Extreme—around a window can prevent it from opening or closing properly.

Note: Always reach out to your local Building Code Professional prior to selecting which Tytan Professional product to use on your job.

Control and Technique

Each spray foam and applicator works a bit differently. Installers should understand how to prep the spray foam and the material where it’s being applied. For example, does the can need to be shaken or does the application surface need to be moistened?

Learning how to use the gun’s control knob, maintain consistent pressure, and manage foam curing times helps prevent overuse and waste. Choosing to consistently use a single spray foam insulation brand like TYTAN Professional helps installers further improve consistency over time.

Safety and Compliance

Between those who are choosing, purchasing, and applying spray foam products, there must be an understanding of how to use these products safely and per regulations. A few areas of focus for maintaining safety and compliance include:

- Proper personal protective equipment (PPE)

- Understanding where fire block is required (check out this video on where to find your local building code)

- Ensuring products meet ASTM standards

- Hitting air changes per hour (ACH) targets

Efficiency

By training installers to maintain good habits, contractors can save time and money. Good habits include:

- Cleaning gun applicators when switching between spray foam products

- Fully reviewing preparation, storage, and curing details for each product

- Following best practices for applicator distance and angle, approved temperature ranges, and thickness limits

Choosing a single spray foam brand and sticking with it across projects can help installers increase knowledge, familiarity, and efficiency as they use it day after day.

A Proven Training Framework

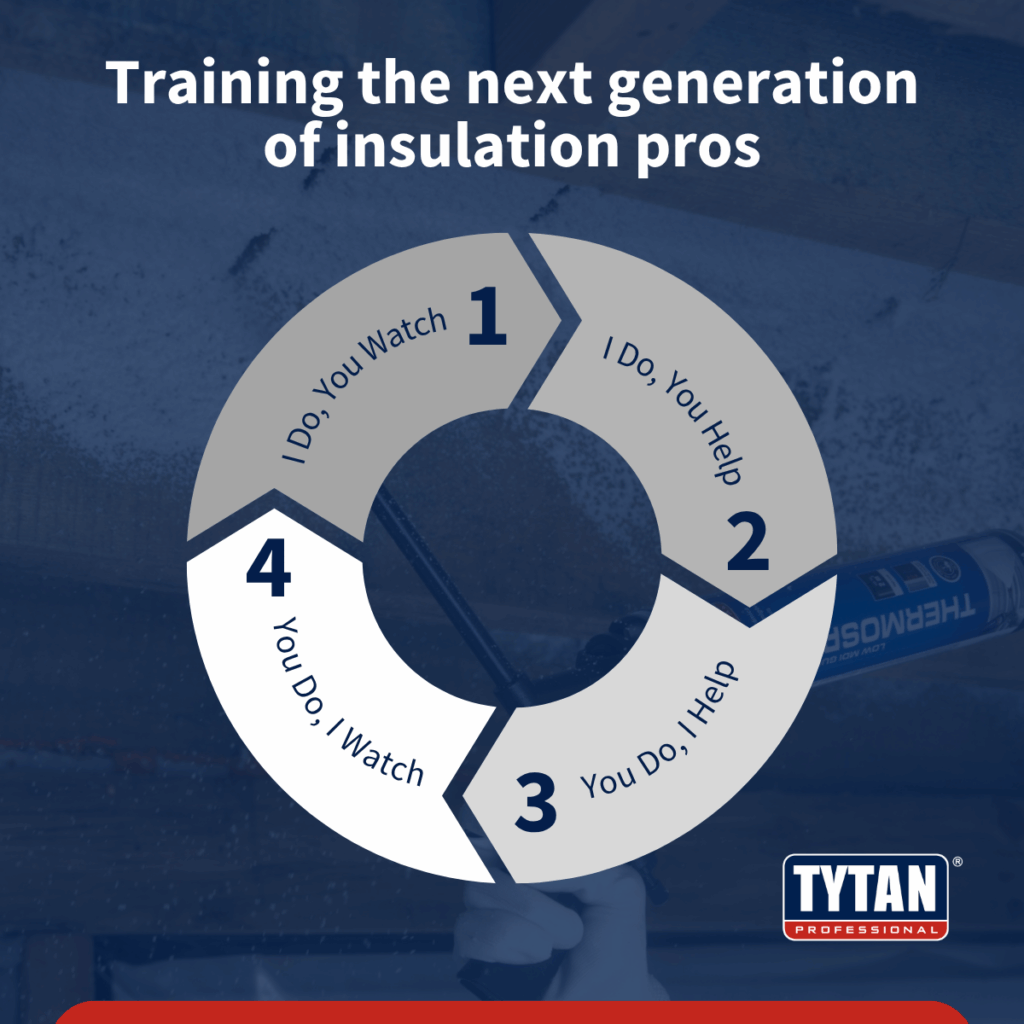

We have seen contractors successfully train insulation (and other) pros with this four-step, hands-on framework:

- I Do, You Watch – The trainer demonstrates the process while the new installer observes closely

- I Do, You Help – The trainee assists the trainer in the process, using what they learned during observation

- You Do, I Help – The trainee takes the lead under supervision, receiving feedback in real time

- You Do, I Watch – The new installer works independently, with the trainer observing and offering final guidance

Depending on work speed and volume, this structure can sometimes be implemented in a single day. Many insulators do three to four houses per day. In this instance, training would flow like this:

- At the first house of the day, the trainee watches

- At the second house, they help with small parts of the process

- By the third house, they’re applying foam while the trainer provides coaching

- By the fourth house, they’re leading the work while the trainer checks results

This approach helps new installers build confidence in logical steps and at their pace, without sacrificing quality or efficiency.

Simplifying Training with TYTAN Products

TYTAN Professional offers solutions designed to make the learning curve smoother and reduce product complexity for new installers.

Thermospray: Easy Spray Insulation

Tytan Professional Thermospray is a one-component polyurethane foam designed to replace traditional two-component spray foam kits that require dialing in Part A and Part B.

Thermospray is pre-mixed and ready to use. New installers can work confidently without worrying about wasted material or mixing errors—ideal for training environments where hands-on practice is key.

Each can of Thermospray yields approximately 21 board feet, and it’s particularly useful for smaller projects, patchwork, soundproofing, or touch-up work. Learn more about the benefits of Thermospray.

Gasket Foam: A Better Seal, Faster

Traditional gasketing strips and caulking can be time consuming and inconsistent. These methods often require staples that puncture the barrier, shrink over time, and are temperature sensitive.

TYTAN Professional Gasket Foam eliminates these issues. It adheres directly to wood, creates an airtight seal, and—importantly—rebounds to seal gaps between the top plate and the drywall.

Gasket Foam is much faster to install than manual sill sealing, and its simple application allows new installers to focus on technique rather than fighting with materials.

Range of Products with Consistent Performance

IBecause we offer a wide range of TYTAN Professional products, installers can become familiar with when to use which product and how to apply it correctly. They can learn the nuances of each product by using the same one day in and day out.

When contractors can trust the quality, performance, and consistency of materials, they can focus on other priorities.

Setting Future Insulation Pros Up for Success

Ultimately, training the next generation of insulation professionals means giving them the tools, knowledge, and structure to succeed. By combining a clear training framework with intuitive, easy-to-use products like Thermospray and Gasket Foam, contractors can shorten the learning curve, reduce rework, and improve job-site efficiency.

Everyone’s happier when the job passes inspection the first time. With the right approach to training and product selection, that goal becomes much more attainable.

For a job well done, choose Tytan Professional Thermospray.